Concrete Crack Repair

A Quick Guide to Polymer Grout Injection

Introduction:

Concrete structures are highly valued in construction for their durability and strength, but even the most resilient concrete can develop cracks over time. Concrete crack repair is essential to maintain both the structural integrity and the appearance of concrete buildings and infrastructure. Among the most effective techniques is polymer grout injection, which includes using polyurethane resins and foams, acrylates, and epoxy resins. This guide explores these polymer-based injection methods, their benefits, and detailed processes to ensure effective concrete crack repair.

Polymer Grout Injection for Concrete Crack Repair

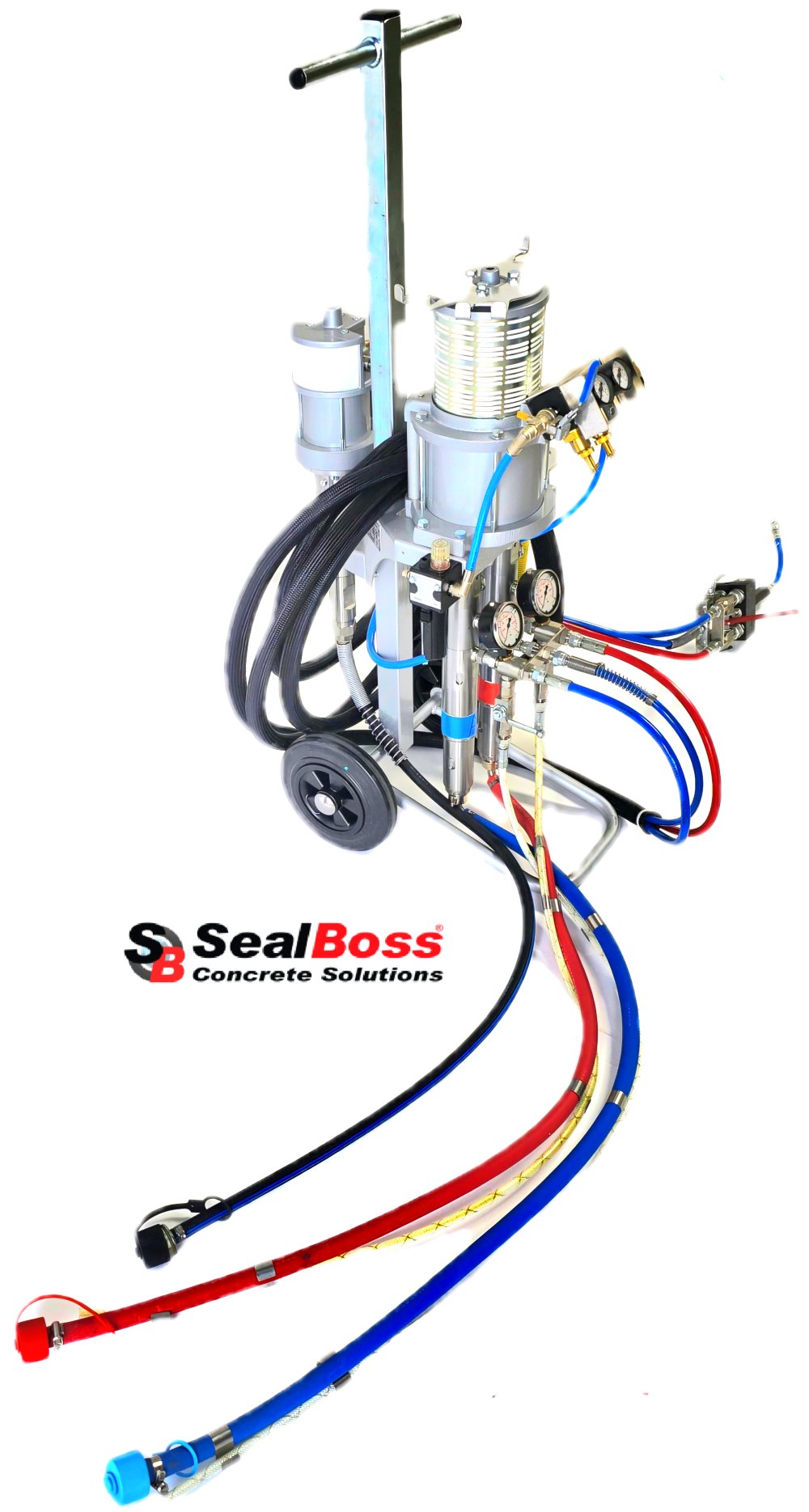

Injection grouting is a versatile and widely adopted technique for concrete crack repair. It involves injecting specialized liquid grouts into cracks within the concrete under pressure.

As the grout hardens, it seals the cracks while either creating a flexible waterproof seal or restoring the structural integrity of the concrete using high-strength bonding agents.

This article covers three main types of polymer grouts for concrete crack repair:

- Polyurethane resins and foams, acrylates, and epoxy resins.

Polyurethane resin and foam are excellent and highly effective for waterproofing and sealing cracks in concrete structures. Known for their flexibility, polyurethane-based resin and foam solutions are ideal for concrete crack repairs in foundations, basements, retaining walls, dams and concrete structures where water ingress poses a significant problem.

Benefits of Polyurethane Injection for Concrete Crack Repair:

- Flexible waterproof seal: Accommodates movement in concrete

- Water stop and moisture barrier: Prevents water infiltration

- Structural reinforcement: Inhibiting further deterioration of concrete.

Process Overview:

- Drill holes at regular intervals along the crack based on conditions

- Clean the cracks and holes

- Install injection packers into the drilled holes

- Inject polyurethane resin starting from the lowest point

- Remove injection ports

Polyurethane resins are ideal for waterproofing as they form a watertight seal, preventing water ingress in basements and other below-grade structures. These resins also add structural integrity to the concrete by filling the cracks and preventing further deterioration.

The injection process begins with drilling holes along the length of the crack at regular intervals. The spacing of the holes depends on the size and extent of the crack. The cracks and drilled holes are then thoroughly cleaned to remove any dust, debris, or contaminants, ensuring proper adhesion of the polyurethane resin.

Injection ports, also known as packers, are installed into the drilled holes to prevent leakage during the injection process. The polyurethane resin is injected starting from the lowest point if the crack is vertical or from one end if it is horizontal, continuing until the resin appears at the next port or from the surface.

After the resin has cured, the injection ports are removed and the surface is cleaned. If necessary, the area is ground or sanded to match the surrounding concrete.

Acrylate injection grouts are popular for concrete crack repair due to their super low viscosity and fast-setting characteristics. Acrylates are well-suited for fine cracks and are often used in curtain injection to create a waterproof barrier behind the concrete.

Benefits of Acrylate Injection for Concrete Crack Repair:

- Super Low viscosity: Penetrates very fine cracks and fissures

- Fast setting: Ideal for curtain injection

- Versatility: Suitable for various leak and moisture conditions

Process Overview:

- For curtain injection drill holes in a pattern at suitable intervals through the structure to create a bladder/curtain seal on the positive side behind the structure

- Clean the cracks and holes to remove contaminants

- Install injection ports

- Inject acrylate grout starting from the lowest point

- Remove ports and clean the surface

Due to their low viscosity, acrylates can migrate through very fine cracks that other grouts cannot, making them ideal for situations where other resins cannot penetrate.

The injection process for acrylates begins with drilling holes along the crack at intervals suitable for the size of the crack. The cracks and holes are then thoroughly cleaned to remove any contaminants.

Injection ports are installed into the drilled holes and securely placed to prevent leakage. The acrylate is injected starting from the lowest point or one end of the crack, continuing until the acrylate appears at the next port or the surface. Once the acrylate has cured, the injection ports are removed and the surface is cleaned.

Epoxy injection is widely recognized for its high strength and bonding capabilities,

Benefits of Epoxy Injection for Concrete Crack Repair:

- High tensile and compressive strength: Restores structural integrity to concrete

- Versatility in viscosity: Can repair both fine and wide cracks

- Outstanding bonding: Forms a permanent bond with the concrete

Process Overview:

- Install surface ports over the crack

- Seal the crack between the ports

- Inject epoxy resin starting from the bottom of the crack

- Remove the ports and finish by cleaning and grinding

Epoxy resin formulations provide high tensile and compressive strength, making them ideal for restoring the structural properties of compromised cracked concrete. Available in varying viscosities, epoxy can be used to repair both hairline and wider cracks.

The injection process for epoxy begins with placing surface ports over the crack and bonding them using a fast setting epoxy paste. The crack between the packers is sealed using the same fast cure epoxy paste to prevent epoxy leakage.

The epoxy resin is injected starting from the bottom of the crack and working up, continuing until the epoxy appears at the next surface port. After the epoxy has cured, the injection ports are removed. If necessary, the area is ground or sanded to match the surrounding concrete.

Conclusion - Why Polymer Grout Injection is Ideal for Concrete Crack Repair

Polymer grout injection—which includes using polyurethane resins, acrylates, and epoxy resins—is one of the most effective methods for concrete crack repair. Each type of grout offers unique properties that make it suitable for specific applications, from waterproofing to structural reinforcement. By following the correct procedures and selecting the right materials, repair professionals can successfully restore and preserve the integrity and appearance of concrete structures.

If you need guidance or technical support for your concrete crack repair projects, consult with industry experts. SealBoss offers comprehensive solutions and expert assistance to help you achieve long-lasting results in your concrete crack repair efforts.