How to Seal Grout Joints in Natural Boulder | Rock | Stone River Seawall

Seawall Leak Repair with SB 1510 Injection Foam

Cold joint and crack injection of grout joints in Natural Boulder | Rock | Stone | River Seawall using the SealBoss 1510 Water Stop Foam – NSF Listed and Drinking Water System Component Approved injection System

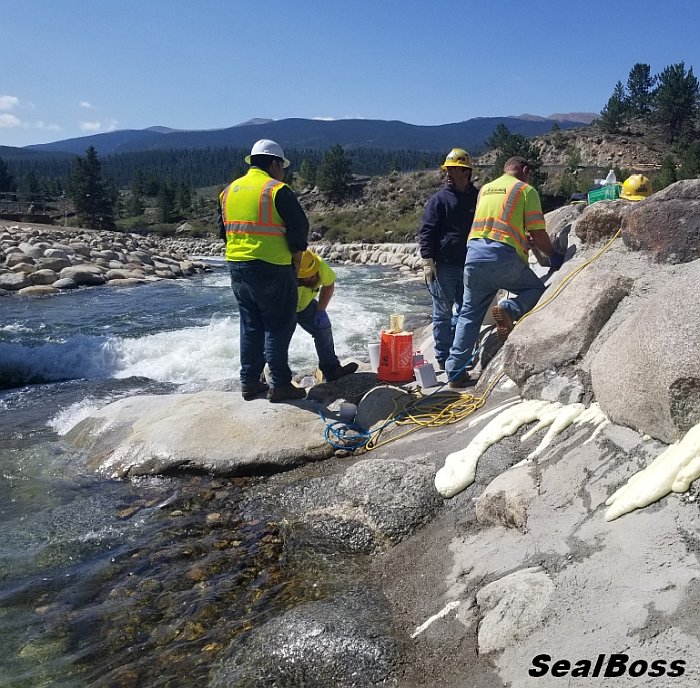

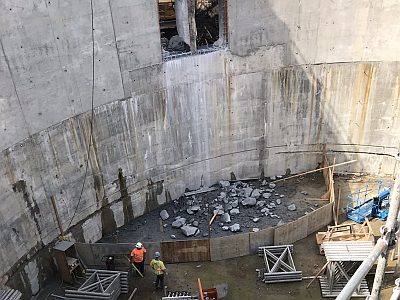

Location: Granite Boat Chute, Arkansas River, Colorado

Objective: To Seal Leaks and Repair Cracks in Seawall Grout Cold Joints

Cold joint and crack injection of grout joints in Natural Boulder, Rock, Stone, River Seawall

SealBoss 1510 Water Stop Foam – NSF Listed and Drinking Water System Component Approved injection System

Along the beautiful and pristine Arkansas river is the Granite Boat Chute. For the first time in more than half a century, rafters and boaters can float the Arkansas River from Leadville to Cañon City without disruption.

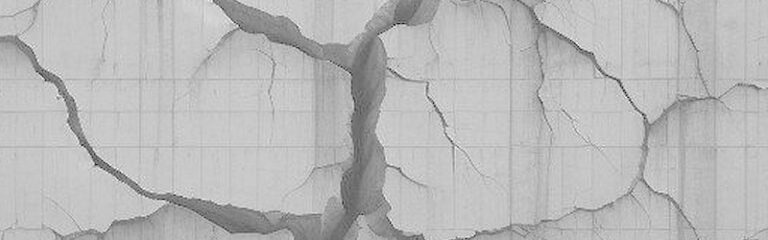

During a repair last season on the divider seawall and re-installation of a section of the boulder wall a cementitious grout was used to bond boulders together and to bond to existing boulders and existing grout. Over time some of the cold joints between the old grout and new grout started leaking. Leaks also developed at bond failures between the natural boulders and rocks, and the cementitious grout. Hairline cracks also developed to contribute to water seepage.

SealBoss 1510 NSF hydro active foam, an environmentally friendly product with NSF drinking water contact certification, was injected into the areas of bond failure to seal the boulder seawall from water intrusion and to prevent future water induced issues with freeze / thaw cycles that contribute to further damages and eventually could lead to blowing out the seawall.

Spacing of the packers was at an interval of 12” and the catalyst was initially at a 5% by volume to allow for travel down in to the areas between the stone to ensure a proper seal throughout the conglomeration. Later the accelerator was increased to a 10% by volume to 1510 to foster a more rapid reaction and cure to fill in some of the remaining voids.

In conclusion, this project outlines innovative solutions that can be employed to address natural wear and erosion challenges.

The use of SealBoss 1510 NSF hydro active foam showcases the potential of polyurethane foam technology in ensuring the longevity and safety of such structures. By addressing the cold joints, bond failures, and hairline cracks, the SealBoss system not only rectified the immediate issues but also fortified the seawall against future damages.

SealBoss ® 1510 NSF Water Stop Foam for infiltrating water:

- Seawall Repair | Crack & Joint Leak-Seal | Soil Stabilization | Permeation Grouting

- Defective Concrete (Cracked or Honeycombed)

- Concrete Construction Joints & Cracks

- Brick Construction, Geo Formations

SealBoss ® 1510 NSF Water Stop Foam Advantages:

- Advanced NSF Formulation

- Up to 40+ Times Expansion

- SealBoss ® Product-Pump-Packer System Solution

- Unregulated For Transport

- Solvent Free MDI Technology

For hands-on or virtual training sessions, please reach out to SealBoss. Our regional technical representatives are ready to guide you through our comprehensive SealBoss system solutions and offerings. Contact us today to schedule your personalized session.

Inquire more about the outstanding SealBoss 1510 NSF Drinking Water Contact Approved Injection Foam when you call us here at SealBoss. Your representative will be happy to help you out.

Leak-Seal Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam Grout

Our #1 Selling Polyurethane Injection Foam

Water Cut-Off Injection Grout

Drinking Water Contact certified – NSF/ANSI 61 Section 5. 1510 PU Foam & Oakum Pipe Plug Kit