Hydrophilic Swelling Waterstop Joint Sealing Profile

Hydrophilic Swelling Waterstop Joint Sealing Profile

Swellable Waterstop - SealBoss SwellTape

What are Hydrophilic Expandable Waterstops?

Understanding Hydrophilic Expandable Waterstops

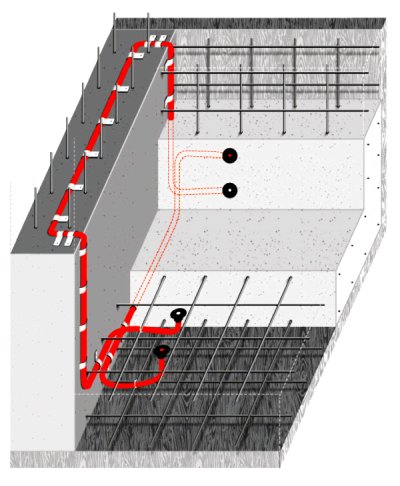

Hydrophilic waterstop PROFILES and SEALANTS are used in construction joints in commercial and residential below ground structures with a low to medium ground water pressure.

Applications include pipe and steel work penetrations through walls and floor slabs, connecting joints in diaphragm walls, construction joints in in-situ and precast concrete, cable ducts and more.

Hydrophilic expandable waterstops, also known as swelling rubber waterstops, are specifically designed to function as sealants that prevent moisture infiltration and water migration in to seal all types of joints and penetrations in concrete, including cold joints and construction joints. These waterstops possess the unique ability to expand by over 400% in volume when exposed to moisture, forming a flexible and watertight compression seal.

Two Types – Profiles and Sealants

Hydrophilic swelling waterstop joint sealing products can be categorized into two types – Profiles and Sealants.

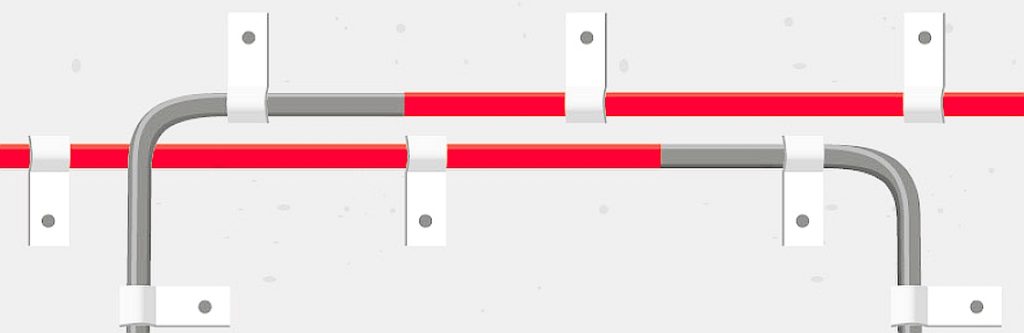

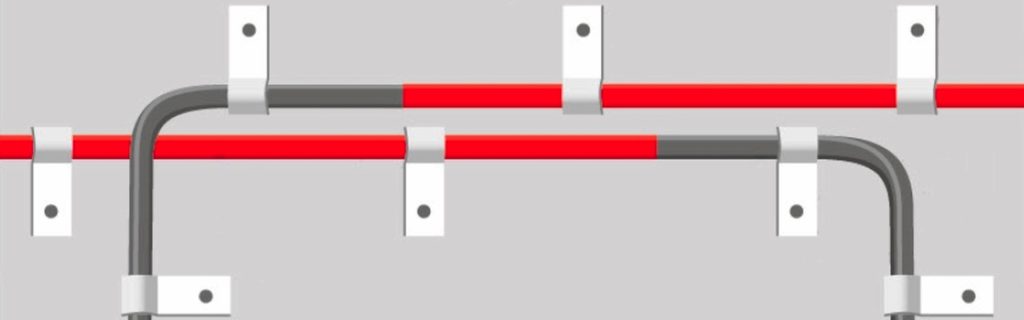

- Profiles: Under the Profiles category, we offer SwellTape, a joint sealing profile that expands in volume while retaining its dimensional stability.

- Sealants: The Sealants category features SwellCaulk, a one-part, moisture-curing polyurethane sealant featuring a balanced expansion rate and distinctive swelling properties.

Application: Expandable Waterstops for Cold Joints and Construction Joints

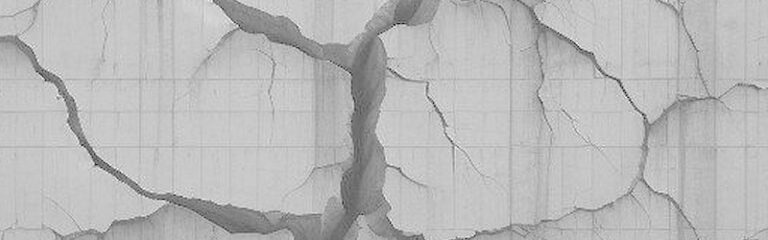

Cold joints and construction joints represent areas in concrete structures that are particularly susceptible to leaks and cracks due to water penetration. Unchecked water ingress can lead to a range of issues that compromise a structure’s integrity, including:

- Rebar corrosion: Water infiltration can cause corrosion in the reinforcing steel, which may weaken the structure over time.

Expansion cracks: Expansive forces resulting from water penetration can lead to the formation of cracks in the concrete - Frost and thaw cycle damages: Repeated cycles of freezing and thawing can cause deterioration in concrete structures, particularly in colder climates

- Health hazards: Mold and fungus growth resulting from moisture infiltration can lead to adverse health effects for occupants.

By employing hydrophilic expandable waterstops in cold joints and construction joints, builders can mitigate these risks, ensuring the longevity and stability of concrete structures.

SealBoss offers an assortment of hydrophilic waterstops that have demonstrated their quality and cost-efficiency in managing water containment issues. These products are suitable for a wide array of applications, whether the goal is to retain or prevent water ingress.

What is SealBoss SwellTape?

SwellTape is a water-activated swelling waterstop synthetic rubber strip used to stop water infiltration through cold joints (see definition below) and concrete construction joints.

Hydro-active SwellTape is an advanced, specially designed, non-bentonite swelling rubber product that reacts with water by gradually and consistently increasing its volume. This expansion is carefully controlled to prevent any potential damage or disruption to the surrounding area. To securely attach the tape to the substrate, it can be embedded in SealBoss SwellCaulk , which acts as an adhesive.

Hydrophilic Swelling Waterstops – Tape Strips and Caulk Options

SealBoss offers a variety of high quality and cost effective hydrophilic waterstops which can be either applied in as tapes or strips, or as gun grade caulk using a caulking gun for a very quick install procedure.

SealBoss state-of-the-art have a proven track record for being a high quality and a cost effective solution.

SwellTape – Pressure Seal

While expanding, SealBoss SwellTape creates a pressure seal, thereby stopping the flow of water through the joint and creating a permanent seal. SwellCaulk can withstand high hydrostatic pressures when installed to specification.

What is a Cold Joint?

A cold joint is the area in the concrete operation, where fresh and existing concrete meet, creating a fine joint caused by a lack of bonding / cohesion of the old and new concrete. The cold joint is created when the original batch of concrete has begun to set (or is fully cured) before the next fresh batch is added. The two batches do not form a strong bond and create a for water to migrate.

SwellTape Applications

- Water Stop and Leak-Seal Caulk for Cold Joints / Construction Joints

- Retaining walls

- Foundations

- Slabs on Grade

- Tunnels and culverts

- Dams, Canals

- Pipe penetrations

SwellTape Application Advantages

- Works on Smooth, Rough, Irregular Concrete Substrates

- Horizontal & Vertical poured-in-place Concrete Joints

- Expansion Delay Formula to allow Concrete Cure Prior to Expansion

- Reliable and Durable

- Retro-fit and New Construction

- Can withstand high Hydrostatic Pressures

SealBoss Training

Popular Cold Joint / Construction Joint Water Stop Systems Links

Popular Cold Joint / Construction Joint Water Stop Systems Links