Stabilizing Sandy Soils and Loose Soils with with Polyurethanes & Acrylates

Primarily Polyurethanes, but also acrylic polymers, have gained importance as soil stabilization products in sandy soils and loose soils of mixed composition.

When injected into the soil, low viscosity polyurethane grouts and supper low viscosity acrylates can improve the unconfined compressive strength, shear strength, and erosion resistance of soil mixtures that contain variable ratios of sand, silt and clay.

Soil – Erosion and Soil Stabilization with Polyurethane Methods

Soil erosion, often caused by rainfall or other sources of water, is a common threat to engineering structures and landscapes.

Loose particles in predominantly sandy soils provide for low strength and cohesion with decreased resistance to erosion during rainfall or when in contact with any water source such as found along a shoreline.

Soil erosion leads to soil migration and loss of soil can lead to the settlement and cracking of structures and the development of sinkholes.

The erosion of loose and sandy soils can be compounded poor and insufficient soil compaction, affecting structures that are built on, and next to it. Soil erosion is a common threat to highways, roadways, railways, waste containment barriers, commercial buildings, as well as residential homes, driveways and pools.

As a counter measure to this type of erosion, injection of liquid agents such as polyurethanes and acrylates, can stabilize soils by utilizing their specific chemical and physical properties.

Chemical grouts permeate loose and sandy soils and act as a cohesive binding agent — providing structural stability by binding substances together — and locking soil particles in place. Once the grout cures, the injected soils turn into a solid mass with improved compressive strength, shear strength and, ultimately, improved erosion resistance and building foundation support strength. Chemical soil injection grouts can also be an option for areas, where push pile piers, helical piers, and driven sheet piles are not an option.

Advantages of Soil Stabilization with Polyurethane Grouts:

- Provide high strength and durability to the soil

- Resistant to water and chemical erosion

- Improves load-bearing capacity of the soil

- NSF/ANSI Drinking Water Contact products available

- Can be used in a wide range of soil types and conditions, including clay, silt, sand, and gravel

- Low viscosity and easy to inject into the soil

- Quick curing time

- Can be applied in any weather condition

- Minimal disruption to the site during the application process

- Cost-effective solution for soil stabilization and void filling

- Polyurethane foam can be used in a variety of soil stabilization applications, including slope stabilization, foundation repair, and road construction.

Soil Stabilization Polyurethanes and Acrylates, Equipment, and Pumps

- Polyurethane

SealBoss 1510 Polyurethane Injection Grout is a low viscosity permeation chemical grout for the stabilization of soils. SealBoss 1510 is a single component, moisture activated, hydrophobic polyurethane soil grout suitable for stabilizing loose and sandy soils and to remediate sinkholes. NSF/ANSI 61 Certified and Drinking Water Contact approved. - Acrylate

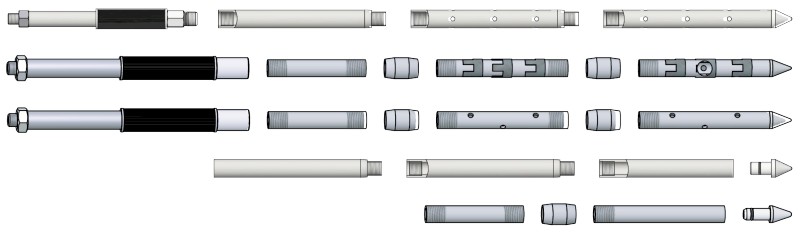

SealBoss 2400SLV Acrylate Injection Grout Gel is a super low viscosity, two component hydrophilic poly acrylate gel with accelerator. The product offers outstanding penetration properties similar to plain water. - Injection Lances

SealBosss Grout Injection Lances are spaced and driven to the required depths required by the application. SB Injection Lances are of modular design and can be assembled to the desired length at the jobsite.

- Injection Needles

SealBoss Injection Needles may be used for more shallow injection and in confined spaces. - Injection Pumps

SealBoss offers a variety of Injection Pumps suitable for small and large soil stabilization jobs. Approximately 0.5 to 1.5 gallons of product are injected into the sandy soils for every foot of depth (5 to 15 liters per meter of depth).

Soil Stabilization Related Articles

- Hydrophobic vs Hydrophilic Polyurethanes

- Permeation & Curtain Injection – Pictures and Podcast

- What Is Dynamic Cone Penetration Testing

- What Causes Unstable Soil? Polyjacking and Permeation Grouting

Learn More

Please don’t hesitate to call us at 714-662-4445 with any questions, or request to be contacted here, we look forward to helping you find a solution. On-site support from knowledgeable and experienced technical reps is available upon request.