Pressure Grouting

Pressure Grouting with Polyurethane Chemical Grouts and Injection Lances

Introduction:

Pressure grouting is an essential technique in construction and civil engineering, enhancing the strength and stability of various structures by stabilizing the subsoil. This method involves injecting grout into voids or cracks in concrete, soil, or rock to fill them and improve their load-bearing capacity. Among the many types of grouts available, polyurethane grouts, a.k.a. chemical grouts, stand out for their unique properties and versatility. In this article, we will explore the intricacies of pressure grouting, focusing on the benefits and applications of polyurethane grouts, as well as the use of injection lances for optimal grout delivery.

What is Pressure Grouting?

Pressure injection grouting in geotechnical applications involves injecting grout under pressure into strata of soil to strengthen the soil by compaction, adhesion and by filling voids, cavities, and fissures. This technique is commonly used for:

- Foundation Stabilization: Strengthening the foundations of buildings and other structures

- Soil Stabilization: Enhancing the load-bearing capacity of soil

- Leakage and Erosion Control: Sealing leaks in soils and structures such as earthen dams

- Void Filling: Filling cavities or voids in rocks or soil

The success of pressure grouting depends on the type of grout used, the injection pressure, and the specific site conditions.

PU Grout Systems for Pressure Grouting Applications

Chemical Grouts

Chemical grouts are fluid materials that transform into a solid or gel state after injection, providing exceptional sealing and strengthening properties. Key features of polyurethane grouts include:

- Versatility: Chemical grouts can be customized for various conditions, making them ideal for a wide range of applications

- Penetration: Due to their low viscosity, chemical grouts can penetrate fine cracks and pores that other grouts might not reach

- Rapid Setting: These grouts can set quickly, which is beneficial for time-sensitive applications

- Longevity: Once set, chemical grouts offer long-lasting stability and resistance to environmental factors

Applications of Polyurethane Grouts

- Permeation Grouting: Used to improve the stability and load-bearing capacity of soils by filling the voids and pores within the soil matrix

- Foundation Underpinning: Supports and stabilizes existing foundations by filling voids and compacting loose soil

- Leak Sealing: Effective in sealing leaks in soil, such as around underground structures and pipelines

- Void Filling: Quickly fills voids in soil, preventing settlement and ensuring stability

Injection Lances for Optimal Grout Delivery

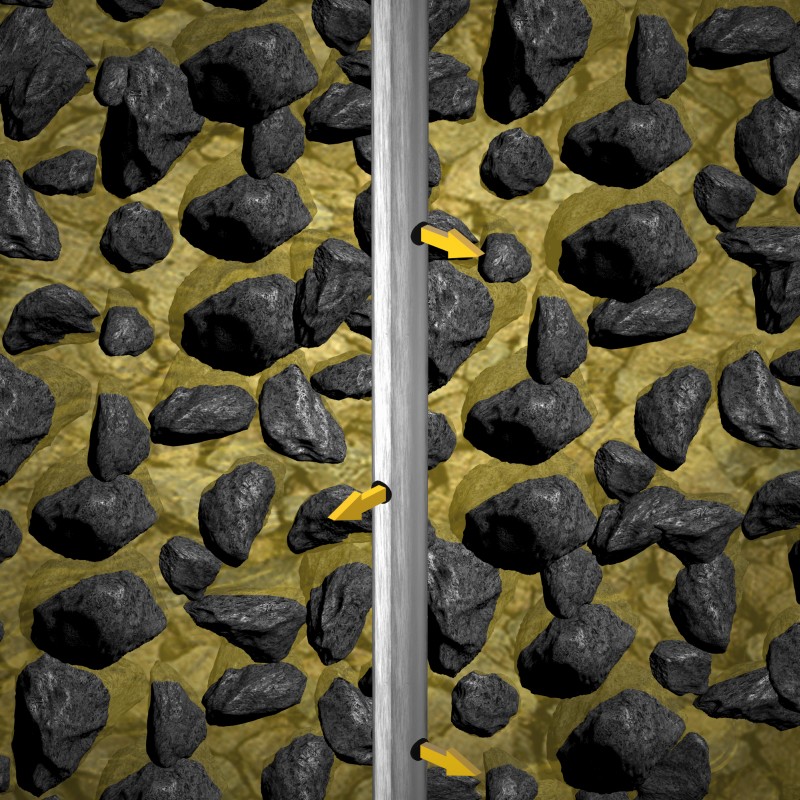

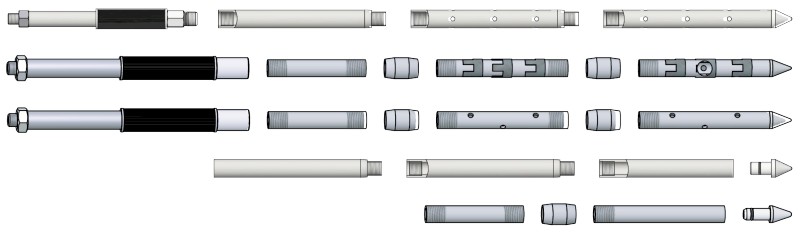

Permeation Grouting Injection Pipes, also known as Grout Injection Lances or Soil Lances, are designed to transport polyurethane grout deep into various soil types. At SealBoss, our injection lances come in distinct versions to provide the best possible grout delivery for different soil compositions.

Advantages of Injection Lances

- Ease of Use: Ram injection lances penetrate soil without the need for large equipment, making them user-friendly and efficient

- Depth Control: Injection lances can be combined to reach specified injection depths, ensuring precise delivery of grout

- Controlled Flow: The lack of a peripheral gap after installation permits controlled flow of injection grouts, enhancing effectiveness

Applications of Injection Lances

- Lower Depth Applications: Ideal for penetrable soils at lower depths

- Permeation Grouting: Effective for improving soil stability by ensuring even distribution of grout

- Soil Stabilization: Enhances the stability of loose or sandy soils

- Foundation Underpinning: Supports and stabilizes foundations by injecting grout at specific depths

- Grout Curtain Injection: Creates barriers to control water flow in soil

- Lifting Applications: Useful for lifting and stabilizing slabs and foundations

- Industrial Foundation Stabilization: Stabilizes industrial machine foundations and slabs.

Choosing the Right Polyurethane Grout and Injection Method for Your Project

Selecting the appropriate polyurethane grout and injection method for your pressure grouting project depends on several factors, including the nature of the soil, the specific requirements of the project, and the environmental conditions. Using injection lances can enhance grout delivery, particularly in soil stabilization and permeation grouting applications.

Conclusion

Pressure grouting with polyurethane grouts, combined with the use of injection lances, offers a versatile and effective solution for soil stabilization and other related challenges. By understanding the unique properties and applications of polyurethane grouts and the advantages of injection lances, engineers and contractors can make informed decisions to ensure the stability and longevity of their projects.

At SealBoss, we provide high-quality grouting solutions and equipment tailored to meet the diverse needs of our clients. Whether you are dealing with foundation issues, soil stabilization, or leak sealing, our range of polyurethane grouts and injection lances can help you achieve optimal results.

For more information on our products and services contact our expert team today!

Related Links