- Installation directly into the construction joint prior to pour

- Can be used in challenging and complex environments

- Highly reliable alternative to traditional joint waterproofing systems

- Suitable for use where adverse weather conditions are expected

- An injectable solution to ensure a watertight joint for the life of the structure

What is the Injection Tube / Injection Hose System ?

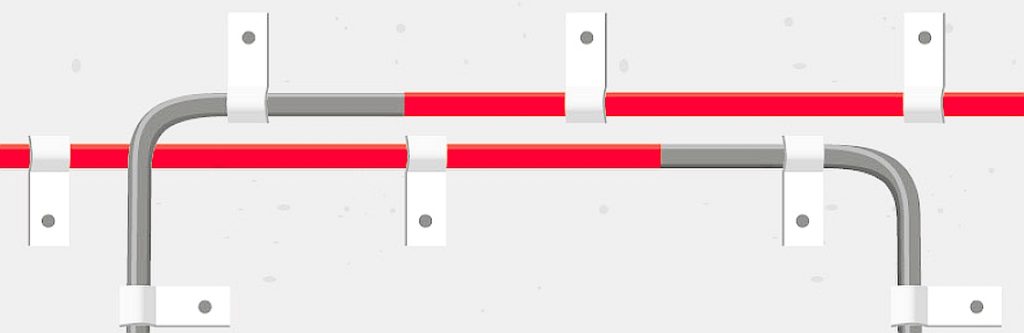

SealBoss Injection Tubes are intricately designed with perforations to serve as a conduit for grout, ensuring a seamless and effective delivery to the required areas.

Injection Tubes are strategically positioned in construction joints before the concrete pour, embodying the epitome of purposeful design and thoughtful manufacturing. These tubes function as a reliable chemical grout delivery system, engineered to seal cold joints in their entirety. This proactive approach results in the formation of a durable barrier, safeguarding the concrete and its embedded rebar from potential damages and corrosion caused by water ingress.

The SealBoss Injection Tube System is an engineered, cutting-edge waterproofing solution, specifically designed to halt water migration through cold joints. These occur when new concrete fails to bond with existing concrete. With its exceptional performance and preventative attributes, our Injection Tube System serves as a critical line of defense in maintaining the integrity and longevity of your concrete structures.

By integrating the SealBoss Injection Tube System into your construction projects, you are choosing a solution that embodies excellence, resilience, and a steadfast commitment to safeguarding your structures against the elements.

How does the Injection Tube / Injection Hose System Work ?

“Often referred to as “inexpensive insurance”, the Injection Tube System is specified by consulting engineers as a built-in safe guard…”

The Injection Tube is installed onto an existing substrate at the interface where new concrete is to be poured. Placed centrally, the tube acts as a delivery system, starting the delivery of SealBoss injection resin from the middle of the seam and penetrating the cold joint evenly to front and back.

SealBoss chemical grout be injected as soon as the concrete has reached enough strength, preferably after the concrete has had time to shrink and/or settle. Careful placement and fixing of the Inject Tube is advised for good success.

Once the encasing concrete has hardened sufficiently, the hose can be injected with SealBoss injection resin or low viscosity polyurethane leak-seal foam.

Primed with resin and then closed at one end with a SealBoss Screw-In Packer and Zerk Fitting, the injection pressure is increased. With rising pressure the low viscosity SealBoss chemical grout is evenly dispensed through the perforated Inject Tube into the cold joint.

After successful installation and injection the cold joint is now permanently sealed in its entirety.