Dam Erosion and Sediment

Dam

Erosion and Sediment

Dam Erosion and Sedimentation Control

with Polyurethane Grout Injection Systems

Dam Erosion and Sedimentation Control with Polyurethane Grout Injection Systems

Introduction:

Erosion and sediment accumulation in dams can present great challenges, threatening the structural integrity and functionality of these important infrastructures. In the face of such risks, polyurethane grout emerges as a game-changer, offering a durable and versatile solution to tackle these problems. This article underscores the advantages of polyurethane grout for dam repair, highlighting its role in ensuring long-term safety and efficiency.

Polyurethane Grout for Erosion, Sediment, and Leak Control

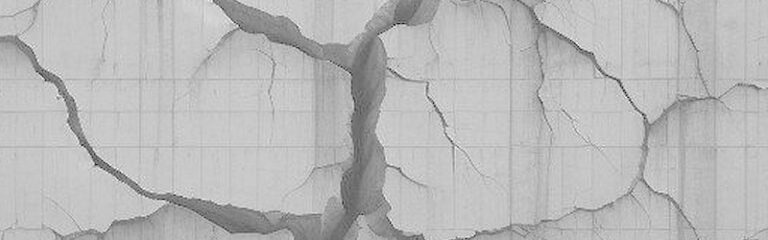

Erosion: A Silent Threat to Dams

Erosion in concrete dams, as well as in earth dams, is more than a maintenance issue; it is a significant risk to their stability and safety. Water seeping through cracks, joints, and fissures gradually erodes concrete and soil, potentially leading to severe damage or failure. Addressing erosion is crucial for maintaining the dam’s structural integrity and ensuring its long-term viability.

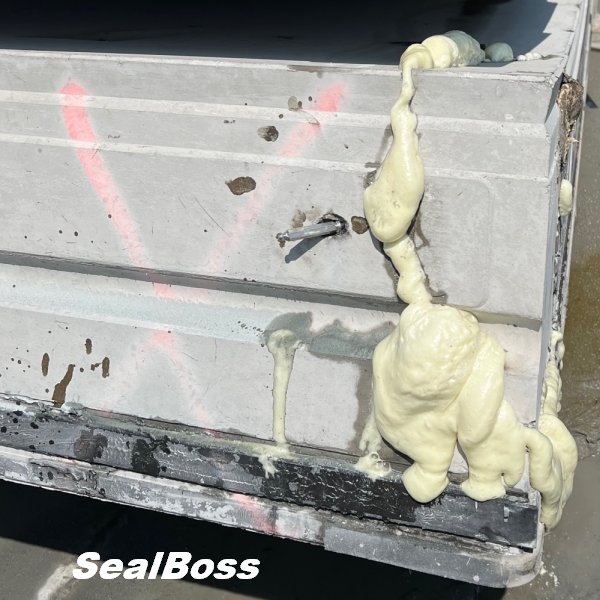

Polyurethane Grout: An Answer to Dam Erosion Challenges

Polyurethane grout stands out as an effective solution to combat erosion. Its flexibility, as opposed to the rigidity of cementitious grouts for example, allows it to adapt to the dam’s natural movements without losing its sealing capabilities. Its quick curing time, hydro-active nature and water stop capabilities are a boon for minimizing operational downtime, especially in essential hydroelectric power generation or water supply dams. Versatile in use, including water stop crack injection, as well as soil stabilization, permeation and consolidation applications, polyurethane grout can be utilized in various dam types and scenarios, addressing a wide range of leakage, sedimentation, and erosion-related issues.

Economic Benefits of Polyurethane Grout

Using polyurethane grout is not only versatile and structurally sound but also economically advantageous. Its durability translates to fewer long-term repairs and reduced maintenance costs. For hydroelectric dams, the quick cure time of polyurethane grout minimizes energy production downtime, making it a cost-effective solution.

Sediment Accumulation: An Underestimated Issue

Sediment build-up in dams, often unnoticed until it becomes problematic, can reduce storage capacity and increase structural pressure. This build-up can also impede water flow, interfere with spillways, clog turbines, and affect water quality, which is especially important in drinking water sources.

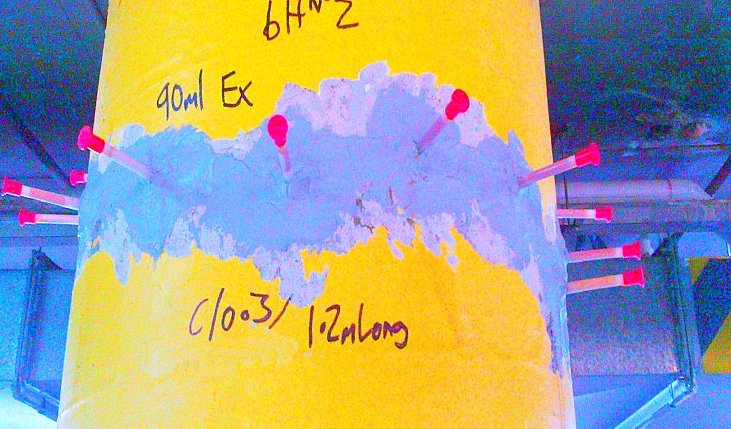

Polyurethane Grout in Sediment Control

Polyurethane grout is invaluable in managing sediment challenges, in earthen and concrete dams. It can be used to create impermeable barriers, seal cracks, crevices, and joints, and solidify and stabilized substrate, effectively stopping sediment inflow.

Energy Efficiency in Dam Management

In dam management, optimizing energy production is crucial. Structural weaknesses and leaks can negatively effect a dam’s energy generation. Using polyurethane grout to seal these leaks supports maximum energy output and prolongs the infrastructure’s integrity and lifespan.

Environmental Safeguards and Polyurethane Grout

The environmental implications of dam leaks can be significant. Leaks may carry contaminants into natural waterways, harming aquatic life and ecosystems. NSF-Certified Polyurethane Grouts offer an environmentally safe solution for leak sealing, contributing to environmental sustainability.

Dam owners and operators can take several steps to address erosion and sedimentation effectively, including but not limited to:

- Comprehensive Inspection: Conduct thorough inspections to identify areas affected by erosion.

- Expert Consultation: Seek advice from engineers and contractors specializing in dam maintenance.

- Quality Material Selection: Opt for high-quality polyurethane grout from reputable manufacturer.

- Professional Contractor Hiring: Choose experienced contractors with a proven track record in using polyurethane grout.

- Regular Monitoring: Implement regular monitoring and inspections post-repair to ensure ongoing effectiveness.

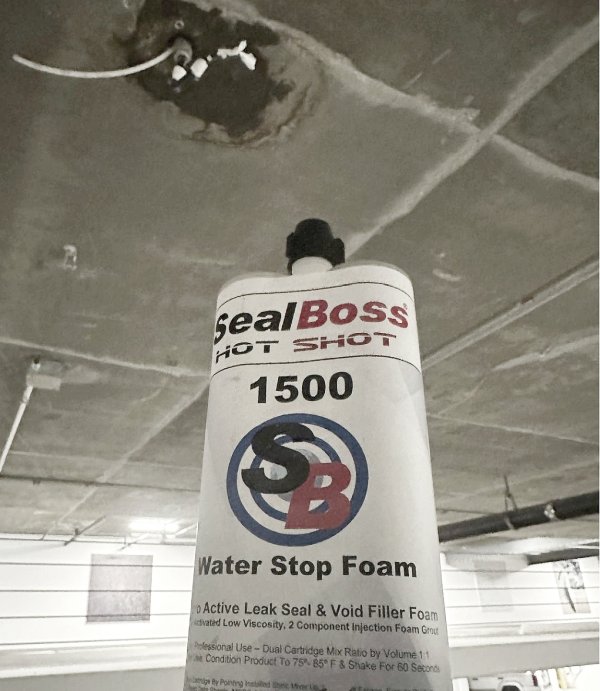

Contact SealBoss for Expert Assistance

For specialized expertise in dam repair and sealing leaks, SealBoss offers decades of experience in developing premium polyurethane grouts. We provide custom recommendations, insights, and referrals to qualified contractors skilled in crack and joint repair, curtain wall grouting, and waterproofing.

Conclusion

Polyurethane grout injection systems are a robust, durable, and economically viable solution for addressing erosion, sediment accumulation, and various leaks in concrete dams and earth dams.

Its versatility and effectiveness make it an essential tool in maintaining the safety, longevity, and operational efficiency of dams. By adopting this innovative solution, dam owners and operators can safeguard their infrastructure and the communities they serve.

Call to Action

For tailored solutions in enhancing your dam’s safety and efficiency with polyurethane grout, contact SealBoss at 714-662-4445 or use our Contact Form. Let our expertise guide you in maintaining your dam’s integrity and functionality.

Related Links

Residential Wet Basement Solutions – Polyurethane Injection

Residential Wet Basement Solutions – Polyurethane Injection