IP2C G2

Premium Acrylate Gel Injection Pump

Stainless Steel Pneumatic Gel Injection Machine

Cutting-Edge Technology for Acrylate Gel Injection and Pressure Grouting Applications

SealBoss ® IP2C

Generation 2 Gel Injection Pump Features

- Highly Upgraded and Improved

- 3 Pump Units | 2 Product / 1 Water

- Stainless Steel Pumps & Applicator

- Sophisticated Design, Simple Operation

- Heavy Duty / High Reliability

- 3000 PSI

- 1:1 Mix Ratio

- High Metering Accuracy

- Separate Flush Pump

- Pressure Lines Included

- Easy To Use / Clean

Application Areas

- Curtain Injection

- Crack Injection

- Building pit waterproofing

- Soil Stabilization & Consolidation

- Cavity filling

- Subsequent horizontal barrier

- Sewer rehabilitation

Range of Applicable Materials

- Acrylate Gel / Acrylic Injection Gel

- Water / Flush Pump

Product Overview

Introducing the new SealBoss® IP2C Gen 2 Gel Injection Pump: The next generation in acrylate gel injection technology

This advanced system sets new benchmarks in performance, design, and functionality.

Featuring a robust stainless steel pumping system equipped with a state of the art applicator, this pump is designed for durability, precision and outstanding protection from corrosion.

The SealBoss® IP2C Gen 2 polymer pump represents the pinnacle of modern engineering, boasting a robust stainless steel pumping system, equipped with a state of the art applicator, and designed for unparalleled durability, precision, and outstanding resistance to corrosion.

This pump is outfitted with a specialized water flush system, making it ideally suited for use with acrylate gel injection products. Its construction and features are meticulously tailored to ensure optimal performance and longevity in demanding environments.

The complete package includes a set of three 15-foot high-pressure hoses and a matching set of suction hoses.

Each component is pumped independently through two product component pumps and an independent water pump. They combine in the heavy duty applicator’s mixing head, flowing through a disposable plastic element static mixer.

Built-in check valves ensure there is no cross-contamination between components. The integrated high-pressure flush pump provides for easy cleaning of the mixing chamber through a separate flush line whenever work is paused.

The system works with various sizes and designs of buttonhead packers, enhancing compatibility with our robust and reliable injection pump. We recommend using our SealBoss Buttonhead Injection Packers and SealBoss Super Flexible Acrylate Gels with this pump for optimal performance and results.

Cleaning Procedure with Water when used with Acrylate Gel

For brief interruptions in the injection process, the mixing head can be efficiently flushed using water or a suitable flushing agent via the dedicated flush pump, which includes a separate suction tube and flush pressure line. Simply switch the applicator handle to flush mode.

Upon completion of the injection, the entire pump system requires thorough flushing. Insert the suction hoses into a tank filled with flushing agent and cleanse all hoses by operating the pump at a lower pressure setting. This ensures the system remains in peak condition for future applications.

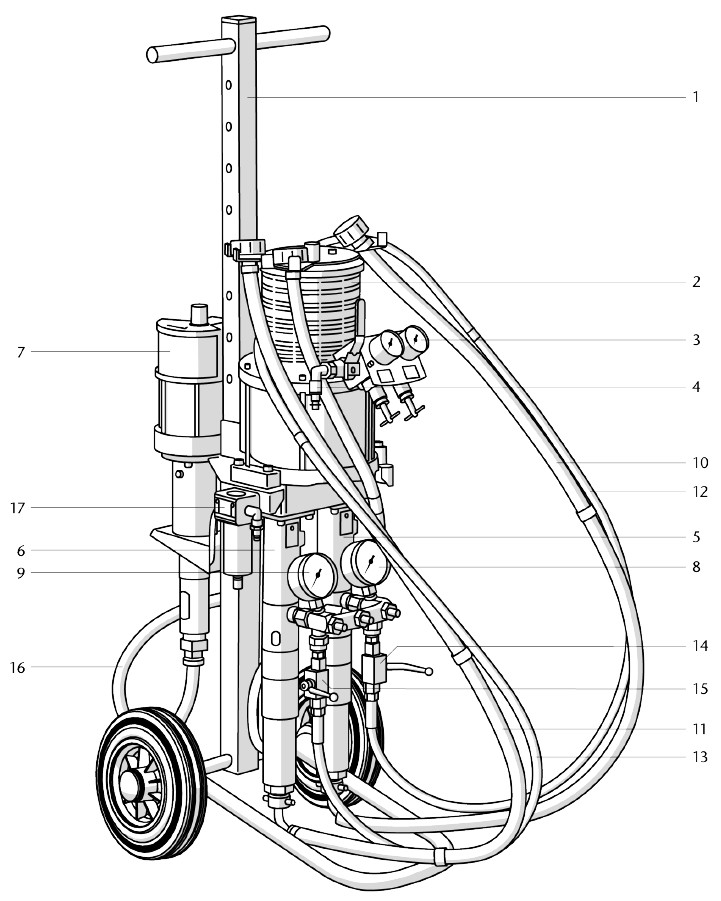

IP2C Schematic

Description

1 – Cart frame

2 – Air motor

3 – Compressed air regulation unit

4 – Compressed air connection

5 – Material pump comp. B

6 – Material pump comp. A

7 – Flushing pump

8 – Pressure gauge comp. B

9 – Pressure gauge comp. A

10 – Material suction hose comp. B

11 – Material suction hose comp. A

12 – Bypass comp. B

13 – Bypass comp. A

14 – Ball valve comp. B

15 – Ball valve comp. A

16 – Suction hose for water

17 – Water separator attachment kit