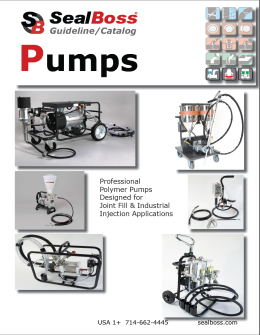

PA 3000 Epoxy Injection Pump

Two Component Pneumatic Epoxy Injection Machine

SealBoss ® PA 3000 Epoxy Injection Pump

Advanced Design Features

- Complete Set Including Hoses And Applicator

- 800 PSI

- 2:1 or 1:1 Mix Ratios

- 3″ Air Cylinder

- Positive Displacement Piston

- Pressure Lines Included

- Compact and Lightweight

- Rugged Construction

- Very Affordable

- Easy To Use / Clean

- Reliable, Proven Design

Product Description

The SealBoss ® PA 3000 Epoxy Injection Pump combines high quality with a very competitive price.

The SealBoss ® PA 3000 Epoxy Injection Pump sets new standards for performance and features.

The machine is furnished with male hose adapters and push-in tube connectors for the pneumatic lines. Hoses are available in a variety of sizes. We also supply surface ports in several sizes and split sets for multi port injection. Please refer to our data sheet on the The SealBoss ® Epoxy Injection Multiple Port System for further information.

The SealBoss ® PA 3000 Epoxy Injection Pump is suitable for the two component SealBoss ® Epoxy Injection Line products and Polyurethane Resins and related products with viscosities between 10 and 1000 cps. Contact your SealBoss ® technician to confirm that your product is suitable for use with this machine.

The SealBoss ® PA 3000 Epoxy Injection Machine has been refined and improved over many years for highest reliability and daily use. The pump features a three inch air cylinder for pressures up to 800 psi. The higher injection pressures allow for better performance with thicker resins and with all materials at lower temperatures.

The tanks are unitized and mounted on four easy roll caster wheels with breaks. The machine is very mobile. The pump is available in 2:1 or 1:1 mixing ratio versions. With purchase of a separate piston/cylinder unit mixing ratios can be easily interchanged.