Joint Filler / Floor Crack Repair

Horizontal Joint Filler - Crack and Spall Repair

Floor and Road Repair

QuickFix System

Polyurea, Polyurethane and Epoxy

10 Minute Concrete Crack Mender

Fast Cure Joint Fill

Floor Joint Fillers and Floor Crack and Spall Repair

SealBoss offers a complete industrial strength repair solution for concrete slabs, decks and traffic surfaces.

Repair cracks, spalls and fill joints in all types of industrial and commercial floors, including warehouses and road surface spot and pothole repair.

With a wide application temperature range, freezer floors in below freezing temperatures can be effectively repaired with the QuickFix system. Supplied in bulk and in cartridges.

The SealBoss JointMaster, is a heavy duty joint filler and crack mender dispensing pump designed to work with all of our repair products. The machine is availabel in 110v and 220V versions and distributed worldwide.

Product Quick Reference

SealBoss ® 6500 Polyurea Joint Filler and SealBoss ® 6500 UVR are for filling construction and control joints in industrial and commercial concrete floors. 6500 is based on the latest polyurea technology which offers outstanding advantages and properties in terms of application speed, fast cure and low temperature application suitability. The durability, ease and speed of application result in a superior and very economic repair solution for the contractors and project owners.

SealBoss 6500 can be shaved flush with the floor shortly after placement. 6500 supports and protects joint edges from heavy loads such as wheel traffic by reducing spalling of the joint edges. Available in standard colors and neutral base formulation to be colored with many custom color SealBoss COLOR PACKS.

SealBoss ® 6880 EP is an epoxy based joint filler with a longer cure time than SealBoss 6500 polyurea. This two component, 1:1 ratio, low viscosity, heavy duty, joint filler is designed to protect joints and joint edges in industrial concrete floors from traffic and load related damages and spalling. The product is also suitable for standard floor joint and floor crack repair.

SealBoss ® 6060 is used for high strength floor and road tough concrete crack and spall repair for concrete slabs, decks, high traffic surfaces, industrial and commercial floors. Now you can repair freezer floors in below freezing temperatures.

SealBoss® 6060 QuickFix is an advanced polyurethane formulated, low viscosity, rapid set, high strength, ultra low viscosity, self leveling, 100% solids and solvent free product. This strong and rigid 10 minute rapid set spall and crack mender has been designed to fix spalled concrete surfaces and cracks, and to rebuild damaged control joints effectively and quickly.

SealBoss® 6060 works for concrete road asphalt repairs. The nearly water thin SealBoss 6060 concrete crack and spall mender penetrates into small cracks and forms a high strength adhesive bond between broken structures with the benefit of sealing the base against further erosion from water in outside applications.

SB 6060 – High Strength Patch and Stitch Concrete Crack Mender:

Patch – SealBoss 6060 is used to repair damaged and uneven concrete surfaces

Stitch – The product penetrates deep into cracks and fissures — welding the surfaces together by creating a strong, monolithic bond

Professional grade formula for for industrial, commercial and residential concrete floors.

SealBoss ® 6880 EP is an epoxy based joint filler with a longer cure time than SealBoss 6500 polyurea. This two component, 1:1 ratio, low viscosity, heavy duty, joint filler is designed to protect joints and joint edges in industrial concrete floors from traffic and load related damages and spalling. The product is also suitable for standard floor joint and floor crack repair.

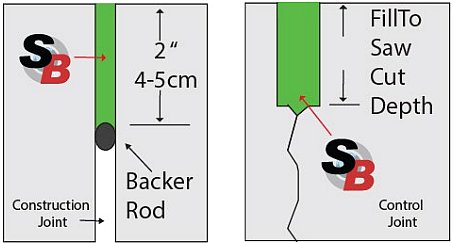

Saw-Cut Control Joints

Per American Concrete Institute, ACI 504R-12

- A minimum 3:2 (depth:width) shape factor is preferred

- Please refer to the ACI Guideline for detailed recommendations

- Depth of joint to be 2″ (50 mm)

- For joints exceeding 2″ (50 mm) use backer rod or other approved method to create 2″ (50mm) joint depth

- Do not use backer rod in joints with depths less than 2″ (50mm)

- Joint width typically predetermined by engineer during planning and construction

The SealBoss 6500 QuickFix Line offers new properties in terms of application speed, low temperature cure, durability and feasibility. SealBoss 6500 QuickFix is a high quality joint and crack filler for concrete substrates in applications that are time critical. It works well in adverse temperature conditions as the material cures in ambient temperatures from -28°C (‑20°F) to 54°C (130°F). The tack free time is 5 to over 15 minutes depending on temperature. This permits to reopen the jobsite to traffic just one hour after application in most conditions.

The SealBoss 6880 EP QuickFix offers heavy duty properties at traditional gel times. SealBoss 6880 EP QuickFix joint filler bonds tightly to the sides of concrete joints, prevents contaminant and water penetration, and delivers high wear resistance and durability. The ambient temperature range for the cured product should be from 40°F (10°C) to +120°F (50°C). SealBoss 6880 EP QuickFix is designed for use on concrete floors.

The SealBoss 6060 QuickFix provides high strength solutions to compliment the Joint Filler products. To ensure a complete chemical cure, color and desired physical properties it is important to premix the product components each sufficiently, condition it to room temperature and to follow the preparation guidelines closely. As with any chemical product, the conditions during the application determine the quality of the results.

Please read guidelines that help ensure a smooth fit and finish and longevity of your repair. Follow the basic application steps for successful joint filling and crack repair applications. Timing For Product Installation The American Concrete Institute (ACI) recommends minimum cure of 30 days before installing joint filler material to prevent adhesion failures, and to allow control and construction joints time to settle to their ultimate width through the concrete cure & shrinkage process. In a controlled freezer/cooler environment floors should be stabilized at general operating temperatures for 7 days prior to installation. Installation should be done during the thermal contraction period of the concrete when it is colder. In hot climates morning hours suit that purpose. High concrete temperatures may accelerate cure process unevenly.

Preparation Of Joints And Cracks It is essential that all cracks and joints are dry at the time of application. Presence of moisture from outside sources or internal concrete moisture content, can cause bubbling and blistering in the cured product. Such affected product must be cut, removed, and reapplied. It is recommended that all cracks be chased and all joints be cut with dustless concrete saw with a diamond blade. The blade must be run along both joint walls (in one pass in narrow joints) to restore concrete surfaces to clean, bare condition. Joints must be completely free of concrete dust and other debris and must be cleaned to their full depth or 2 inch minimum. The absence of debris and freshly cut edges provide the necessary surface to which the polyureas adhere. Any crack and joint contamination and large variations in width and joint proportions may affect the physical properties of the material and joint dynamics and can lead to adhesive or cohesive separations. In most cases when detected early after a fresh installation, separation can be addressed with the addition of more material to the separated areas. Note: In certain scenarios structural failures can cause crack and joint separations running the entire way through the repaired areas . This is not a product failure and must be addressed by structural strengthening of the slab or substrate.

Recommended: Double Pass Method Many potential problems, such as uneven depth, moisture reactions and leakage into the substrate can be minimized by applying the jointfiller in two passes following in short sequence. The first pass should be a quick effort to apply an initial layer of product to the substrate and seal the surface. Any imperfections of the first layer will be covered with second, precisely applied pass minutes later when the filler meets the initial layer and now has a perfectly primed surface.

Types Of Joints

We differentiate Saw-Cut Control Joints (limited depth, cut into slab to prevent mainly shrinkage cracks) and Construction Joints (full slab depth between two concrete pours (forms) by design, to prevent mainly concrete expansion (thermal) cracks). Post Installation Do not remove material overfill prior to full cure. Filler profile must be flush with floor surface to provide proper joint protection. Use appropriate shaving or grinding tools. If filler is concave, a cap bead of additional product can be applied after roughening surface and cleaning with a solvent.

Spall and Crack Concrete Mender and Welder – Floor, Road and Highway

SealBoss 6060 QuickFix has been formulated for highway and other extensive repair projects where a fast cure and permanent solution is needed. Depending on the requirements, SealBoss 6060 T QuickFix can be used with a variety of aggregates including gravels and sands thereby allowing the user to solve several problems with one material. Based on the product’s rapid cure properties, repairs can be completed with minimal traffic closure time.

SealBoss 6060 T QuickFix has excellent chemical resistance to oils, hydraulic fl uids, gasoline, salts, and antifreeze. The product contains no solvents and has no odor. SealBoss 6060 T QuickFix is a fast cure, low viscosity, rapid set, high strength, self-leveling, two component, 1:1 ratio by volume, 100% solids polyurethane polymer for concrete and asphalt repairs. SealBoss 6060 T QuickFix works for concrete and asphalt repairs and is an excellent high strength bonding agent for use with a wide variety of aggregates. The product penetrates into small cracks and forms a high strength adhesive bond between broken structures with the benefi t of sealing the base against further erosion from water in outside applications. The tack free time is 5 to over 10 minutes depending on temperature. Ask your SealBoss technician for details. The product is for professional use.

Installation Guidelines

Clean the area of debris and contaminants, such as oils, loose materials, dirt, rubber etc., to allow for good adhesion of the product. Expose clean rough concrete for best results. If using a saw to cut concrete and clean the crack, remove all the dust from the cutout area. Make sure the surfaces are dry. All equipment, pumps and hoses must be dry. Avoid moisture contact with the mixture. For bulk mixing, pre-mix each component thoroughly. Proportion equal parts by volume of Component “A” and Component “B” through appropriate metered mixing equipment. Mix only the quantity that can be used within pot life and do not allow mixed material to reside in static mixing head or mixer for more than 1 minute or nozzle blockage may result. Do not add solvents. Minimum age of concrete must be 21-28 days, depending on curing and drying conditions prior to applications. Deep Crack / Joint Application Apply product to the bottom of the crack and work up in layers. First apply product, then deliver aggregate into the applied product. Add more product & aggregate. Repeat the steps until reaching the finished grade.

Aggregate

The use of approved non reactive aggregate with SealBoss 6060 T QuickFix may increase gel and cure times. Aggregate must be free of moisture. Dry silica sand and a variety of gravel grades may be used depending on the applications and specific demands of the job site. Maintenance of Equipment Tools and equipment must be cleaned immediately after use. Remove all excess product. Cured product is hard to remove. SealBoss R70 Pump Flush is a solvent free, non-flammable cleaner, lubricator, pump and hose conditioner.