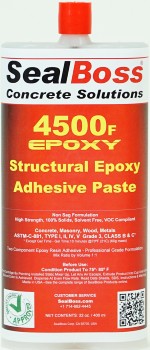

SealBoss 4500 F Epoxy Paste

Hi Mod Gel Adhesive

Quickseal Hi-Mod Gel High-Modulus

High-Strength Structural

Epoxy Paste Adhesive

Applications / Characteristics

- Paste to Set Surface Mount Ports & Seal Cracks prior to Epoxy Injection

- Fast Cure – Non-Sag Formula Epoxy Paste

- Seals cracks and around injection ports prior to pressure‑injection grouting

- High‑modulus, high‑strength, 1:1 ratio

- ASTM C 881 Compliant

- Types l, ll, lV, V Grade 3, Class B & C

Fast Cure High Strength Epoxy Paste

- SealBoss ® Product-Pump-Packer System Solution

- Bulk & Cartridge System

- This Product is for Professional Use

SealBoss 4500 F QuickSeal Epoxy Paste is a fast cure, 100% solids, high modulus, non-sag, non-shrink two component epoxy adhesives that bonds to concrete and other surfaces.

SealBoss 4500 F QuickSeal Epoxy Paste meets or exceeds requirements of ASTM C 881 (Types l, ll, lV, & V Grade 3, Class B & C)

Ask your SealBoss Technician for details. The product is for professional use.

Installation Guidelines

For Bulk Applications

To Seal Cracks for Injection Grouting

Place the mixed material over the cracks to be pressure injected and around each injection port. Allow sufficient time to cure before pressure injecting. Always test a mixed product to insure that the material will harden properly.

As a Bonding Adhesive

Apply the mixed SealBoss 4500 F QuickSeal Epoxy Paste to the prepared substrates. Work into the substrate for positive adhesion. Secure the bonded unit firmly into place until the epoxy has cured.

Surface Preparation

Surface must be clean, dry and sound. Remove dust, grease, waxes, foreign particles and disintegrated materials.

Preparation Work

Concrete

Sand blast or use other approved mechanical means.

Steel

Sandblast to white metal finish.

Bulk Mixing

Pre-Mix each component separately. Mix 1 part A (resin) to 1 part B (hardener) for 3 minutes using a Jiffy Mixer. Mix at slow speed (less than 850 rpm) to avoid air entrapment.

Remember, you will have less working time at higher temperatures. Mix only the quantity that can be used within its pot life and do not allow mixed material to reside in static mixing head or mixer for more than two minutes or nozzle blockage may result. Never thin with solvents. Surface and ambient temperature must be 45°F (7°C) or above. For applications with constant high temperature (above 120°F, 49°C), contact SealBoss®. Material will soften at very high temperatures. Do not expose stored product to cold temperature (below 40°F, 5°C) for any length of time.

Note

High temperature will accelerate the setting time. As a general rule, the gel time of the epoxy will be cut in half for each 10° to 15° increase in temperature above 75°F and the gel time will double for each 10° to 15° drop below 75°F (24°C). Minimum age of concrete must be 7 days and considered fully cured, depending on curing and drying conditions.